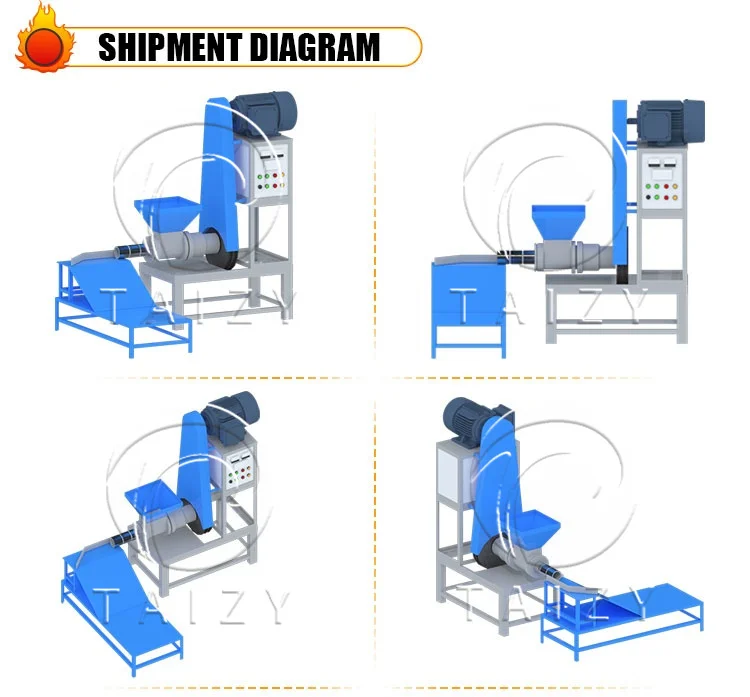

Automatic Biomass Briquette Machine Wood Briquette Press Extruder Machine

SKU: RBL-2025022520251In Stock

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Automatic Biomass Briquette Machine Wood Briquette Press Extruder Machine

Briefing

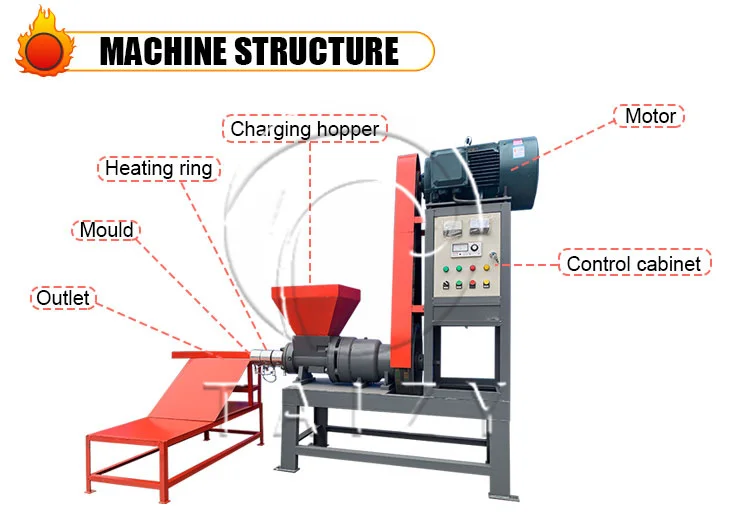

The product is a Good Price Automatic Biomass Briquette Machine. This machine is designed for efficient and precise production of biomass briquettes using advanced technology.

Key Specifications

- Type: Biomass Briquette Machine

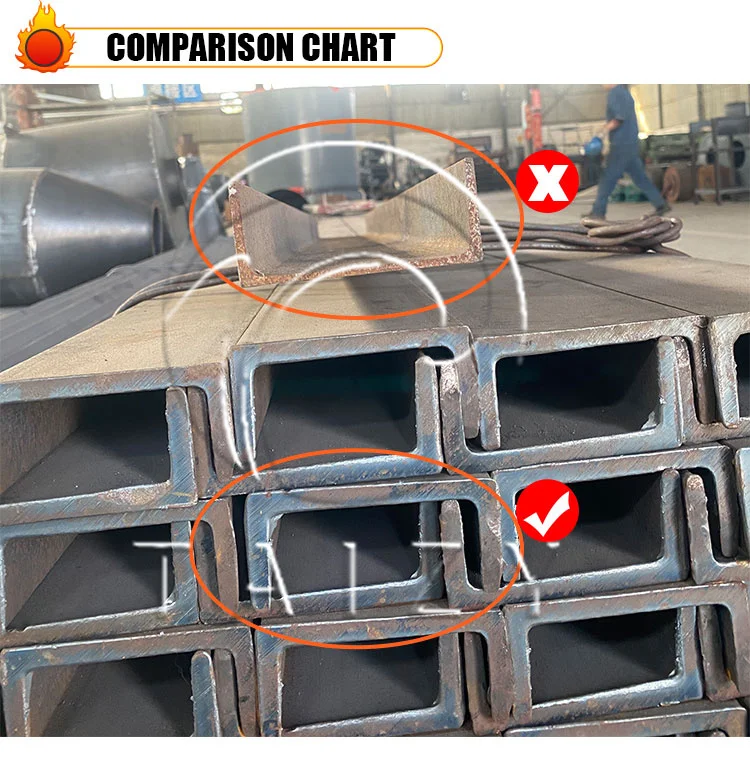

- Material: Steel

- Operation: Automatic

- Power: 18.5 kW / 22 kW

- Voltage: 220V/380V

- Production Capacity: 260-400 kg/h

- Weight: 750-780 kg

- Dimensions: 1.9 x 0.7 x 1.6 m

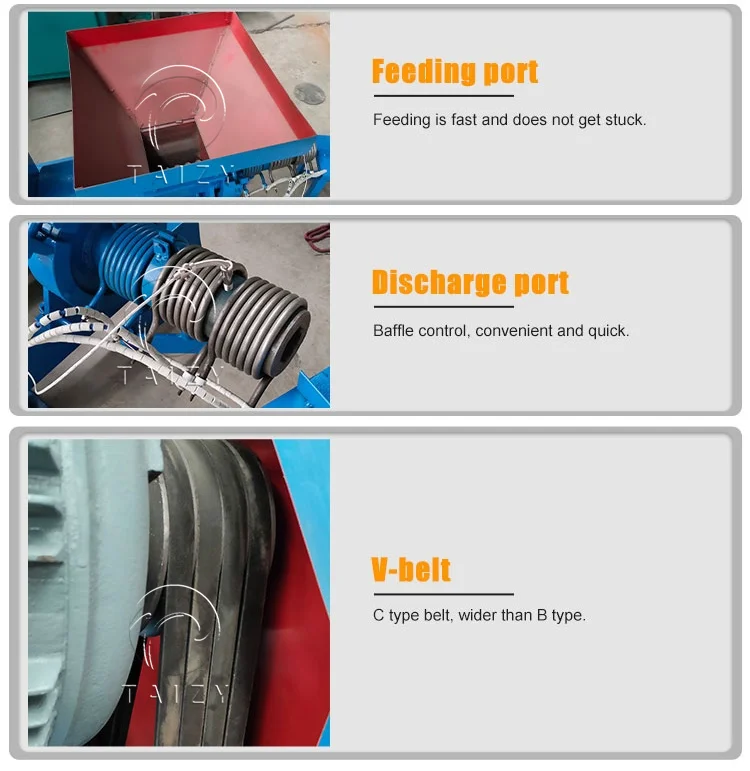

- Control: Electric with auto-control electric heating device

Applications

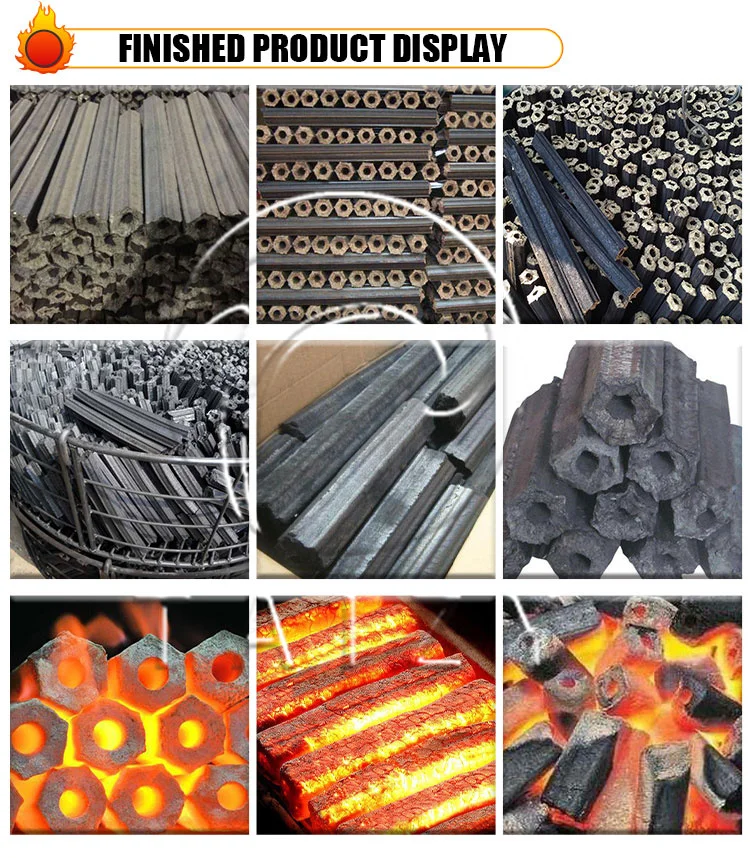

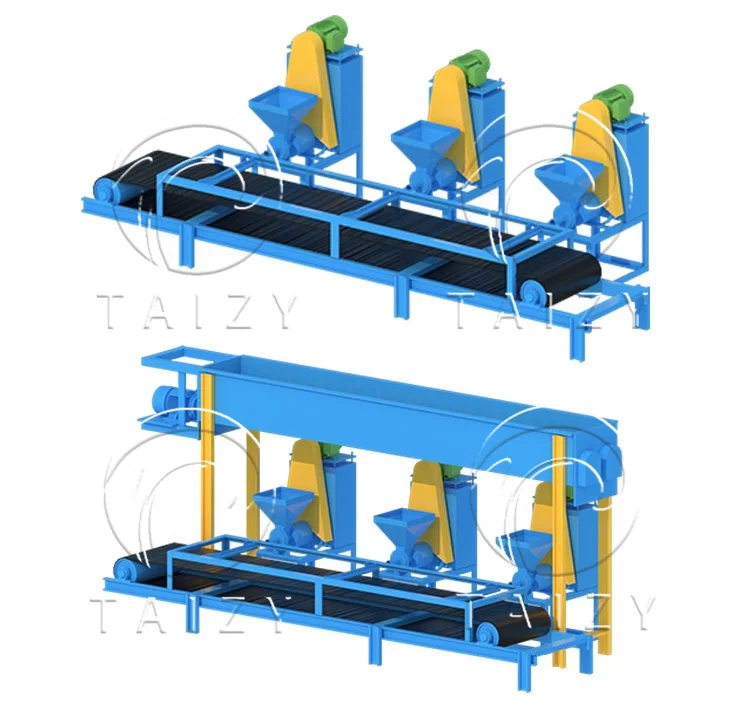

- Biomass Fuel Production: Ideal for producing biomass briquettes from agricultural waste such as rice husk, coconut shell, peanut shell, sawdust, straw, and grass.

- Renewable Energy: Suitable for producing renewable energy sources for heating and cooking.

- Customizable: Can be customized for different sizes and specifications.

Summary

This good price automatic biomass briquette machine offers a powerful and efficient solution for producing biomass briquettes. It is designed for automatic operation with a high-precision control system, making it suitable for use in various industries such as biomass fuel production and renewable energy. The machine is customizable in terms of size and specifications, providing flexibility for different projects. Its durable construction and advanced control features ensure reliable performance.

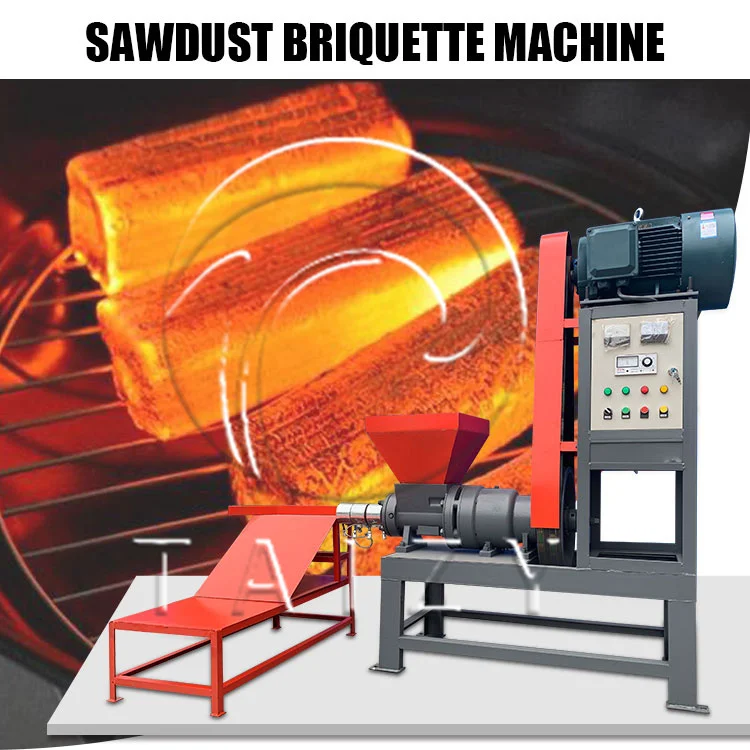

Description of sawdust briquette machine

|

Model

|

Power

|

Capacity

|

|

SL-50

|

18.5-22kw

|

200-300kg/h

|

|

SL-80

|

22kw

|

300-350kg/h

|

Features of sawdust briquette machine