Automatic Bottled Vodka Whiskey Wine Beer Monoblock Filling And Capping Machine

SKU: RBL-46FFPIn Stock

Would you like to know more details of the paste filling machine,pls feel free to contact us.

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

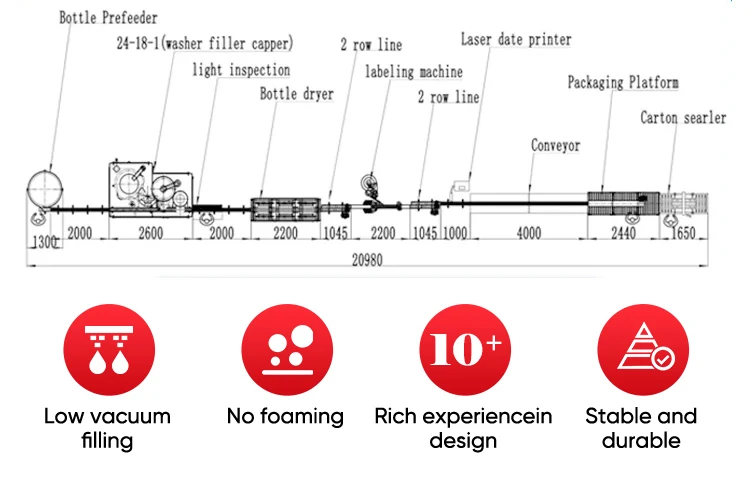

Automatic Bottled Vodka Whiskey Wine Beer Monoblock Filling And Capping Machine

Key attributes

Industry-specific attributes

Other attributes

Packaging and delivery

|

Model

|

XGF14-12-5

|

XGF16-16-5

|

XGF24-24-8

|

XGF32-32-8

|

|

Capacity

|

5000???

|

8000BPH

|

12000???

|

15000???

|

|

Bottle Volume

|

200ml-2500ml

|

200ml-2500ml

|

200ml-2500ml

|

200ml-2500ml

|

|

Bottle diameter

|

50-110mm

|

50-110mm

|

50-110mm

|

50-110mm

|

|

Bottle high

|

150-320mm

|

150-320mm

|

150-320mm

|

150-320mm

|

|

Machine power

|

1.5KW

|

2.2KW 3.7KW 5.5KW

|

3.7KW

|

5.5KW

|

|

Machine size

|

235×177×225CM

|

270×200×225CM

|

280×210×225CM

|

355×265×225CM

|

Automatic Washing Part 1. The washing part will wash the bottles inside and outside automatically. 2. The washing nozzles with big flushing force to make sure more cleaning. 3. The clamping hands with accurate positioning and easy turnover of the bottle. 4. Each clamping hand part is equipped with a control sprinkler device, no bottle no flush, saving water.

Automatic Filling Part 1. The filling nozzles with bottles mouth will forming an low-vacuum in filling process, the liquid will flow into the bottle inside. 2.No bottles no filling, saving liquid. 3.The filled liquid in the bottles are at the same level and filling volume could be adjusted. 4.The filling nozzles adopt quick connection device, easy to clean and maintenance

Capping/ Corking Part As the capping part, we want to do an special introduction for you. The mono block machine could with two function capping and corking together. 1. No bottles no capping/corking , save caps/ corks. 2. Placed corks/caps on bottle mouth automatically, save labors. 3.With perfect sealing effect and pretty outside 4. The capping part could equipped with caps/ corks elevator to achieved automatically conveying caps/corks into vibration bowl or corks hopper.