Bottle Drink Filling Machine Production Line

SKU: RBL-1RQDUIn Stock

Would you like to know more details of the paste filling machine,pls feel free to contact us.

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

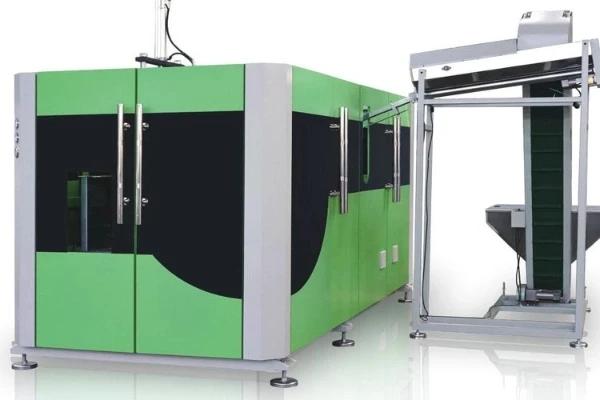

Bottle Drink Filling Machine Production Line

|

Technical parameter

|

|||||

|

Model

|

CGF8-8-3

|

CGF14-12-5

|

CGF18-18-6

|

CGF24-24-8

|

CGF32-32-8

|

|

Capacity(for 500ml)

|

2000

|

3000-4000

|

4000-6000

|

8000-10000

|

10000-12000

|

|

Suitable bottle shapes

|

PET circular or square

|

||||

|

Bottle diameter(mm)

|

Dia50-Dia115mm

|

||||

|

Bottle height (mm)

|

160-320mm

|

||||

|

Compressor air

|

0.3-0.7Mpa

|

||||

|

Washing meidium

|

Aseptic water

|

||||

|

Rinsing pressure

|

>0.06Mpa <0.2Mpa

|

||||

|

Application

|

pure water, mineral water, spring water

|

||||

|

Total power (KW)

|

4.4kw

|

4.4kw

|

4.4kw

|

5.2kw

|

6.2kw

|

|

Overall dimensions

|

2.3*1.9m

|

2.5*1.9m

|

2.8*2.15m

|

3.1*2.5m

|

3.8*2.8m

|

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

|

Weight(kg)

|

2500kg

|

3200kg

|

4000kg

|

4500kg

|

6500kg

|

/Raw water tank + Raw water pump

/ Silica sand filter + Active carbon filter + Sodium ion Exchanger + Precision filter + Security filter

/ Reverse Osmosis (one level)

/UV sterilizer

/ Finished water tank + Pure water pump

Water Filling Machine [ Washing Filling Capping 3 in 1 type ]

/ All 304/316 stainless steel material, water spray style inject design, more save water consumption and more clean

/ Filling volume adjustable in fine rank, same filling liquid level .No bottle no filling,no bottle no capping

/ Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

/ Hygiene improvement through volume control and contactless filling

/ Automatic dummy bottles: Safer, easier cleaning procedures

/ Automatic bottle changeover improves uptime

Washing part

III 304 stainless steel washing pump

Filling part

III All 304 stainless steel contact parts &

liquid tank, fine polish, no death corner, easy to clean

V no bottle no filling

Capping part

I Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

Labeling & Packing Part

This hot melt glue plastic bottle label applicator is widely suitable for different material of container and label. The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most

economical models in cost to make mass production and inter grated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate

or manual speed adjustment to automatic speed control, for example changing the label is only needed to change the program, the products concept of that the equipment is designed for users is embodied in everywhere.

Flat Conveyor.

– Energy saving. High efficient. Adapt to customer factory layout

– Special lubrication system, keep products clean, health, safety

– Extended service life

– Electric eyes design keep whole line running safety and quickly

– Overload protection mechanism to effectively ensure the safety of the machine