Filler Control Touch Screen Automatic Rotary Small Bottle Cosmetic Essential Oil Filling & Gluing Machine

SKU: RBL-B93OZIn Stock

Would you like to know more details of the machine, please feel free to contact us.

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

|

Bottle washing filling and capping 3 in 1 machine

|

|||

|

Model

|

GFFDP18-12-4

|

GFFDP24-18-6

|

In addition to these models, we can customize according to your output requirements, so please contact us and tell us your needs

|

|

Number of bottle washing heads

|

18

|

twenty four

|

|

|

Number of filling nozzles

|

12

|

18

|

|

|

Number of capping heads

|

4

|

6

|

|

|

Production capacity (Depends on bottle capacity):

|

3000-4000 BPH (50ml)

|

5000-6000BPH (50ml)

|

|

|

Total power

|

3 (kw)

|

5.5(kw)

|

|

|

weight

|

2500KG

|

3500KG

|

|

|

Dimensions

|

3800*1500*2200mm

|

4200*1500*2200mm

|

|

|

Bottle height:

|

50-320 (mm) customized

|

||

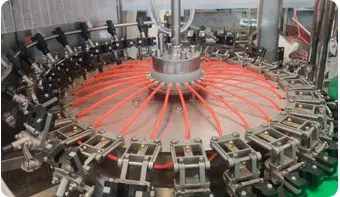

1.WASHING PART

The machine cleans the inside and outside of the bottle and can increase or decrease production by adjusting the number of bottle cleaning clips

2. FILLING PART

Using flowmeter or negative pressure or piston filling principle, bottles can be customized.

3. SEALING PART

Can be sealed for various sizes. Fully automatic cap, no bottle without cap. Maximum output can reach 30,000 bottles per hour.

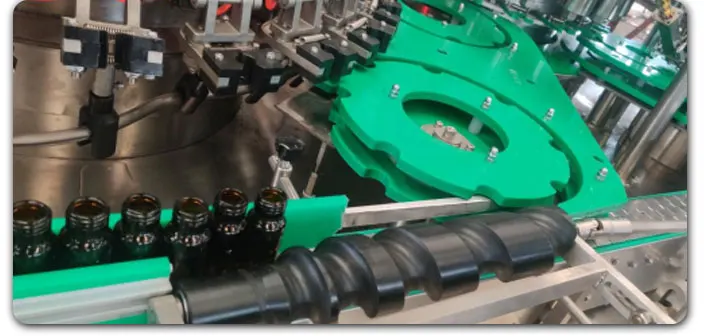

4.LID LIFTING MACHINE

The function of the lid lifting machine is to automatically transport the lid to the sealing part and fix the lid to the bottle. It improves production efficiency and saves labor.

|

Bottle washing filling and capping 3 in 1 machine

|

|||

|

Model

|

GFFDP18-12-4

|

GFFDP24-18-6

|

In addition to these models, we can customize according to your output requirements, so please contact us and tell us your needs

|

|

Number of bottle washing heads

|

18

|

twenty four

|

|

|

Number of filling nozzles

|

12

|

18

|

|

|

Number of capping heads

|

4

|

6

|

|

|

Production capacity (Depends on bottle capacity):

|

3000-4000 BPH (50ml)

|

5000-6000BPH (50ml)

|

|

|

Total power

|

3 (kw)

|

5.5(kw)

|

|

|

weight

|

2500KG

|

3500KG

|

|

|

Dimensions

|

3800*1500*2200mm

|

4200*1500*2200mm

|

|

|

Bottle height:

|

50-320 (mm) customized

|