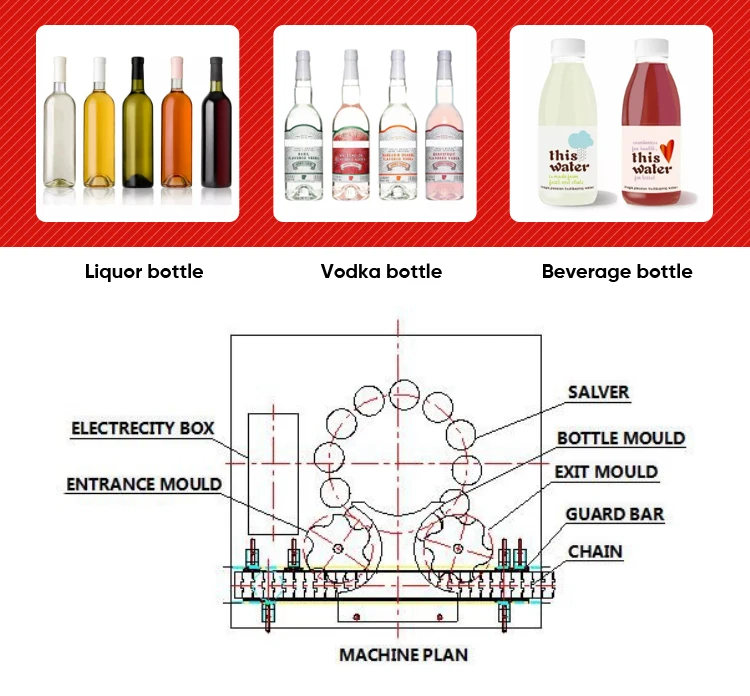

Glass Bottle Wine Processing Plant Whiskey Vodka Beer Production

SKU: RBL-0QEH0In Stock

Would you like to know more details of the paste filling machine,pls feel free to contact us.

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Glass Bottle Wine Processing Plant Whiskey Vodka Beer Production

Key attributes

Industry-specific attributes

Other attributes

Packaging and delivery

? Spraying filling: Liquid flows down along the sides of the bottles to ensure the filling quality ? No bottle broken: bottle holding devices can flexibly adjust bottle location, avoiding any possible bottle damage or even machine damage. ? Long service life and easy maintenance.

|

Description Name

|

Parameters

|

Parameters

|

Parameters

|

Parameters

|

|

Model

|

GFGFP-12

|

GFGFP-18

|

GFGFP-24

|

GFGFP-36

|

|

No. of filling heads

|

12

|

18

|

twenty four

|

36

|

|

Production capacity per hour

|

2000~2500bmp

|

3000~4000bph

|

5000~6000bph

|

8000~10000bph

|

|

Applicable bottle height

|

160~360mm,could be customized

|

|||

|

Filling accuracy

|

±1.5 mm

|

|||

|

Applicable bottleneck diameter

|

F50-F100,could be customized |

|||

|

Overall dimension(L*W*H)

|

1200*1200*2200mm

|

1500*1500*2200mm

|

1800*1800*2200mm

|

2500×2350×2200mm

|

|

Capability(b/h)

|

3000

|

4500

|

6000

|

10000

|

|

Weight

|

700Kg

|

900KG

|

1500KG

|

2000kg

|

|

Power

|

1.12

|

1.12

|

1.85

|

3

|

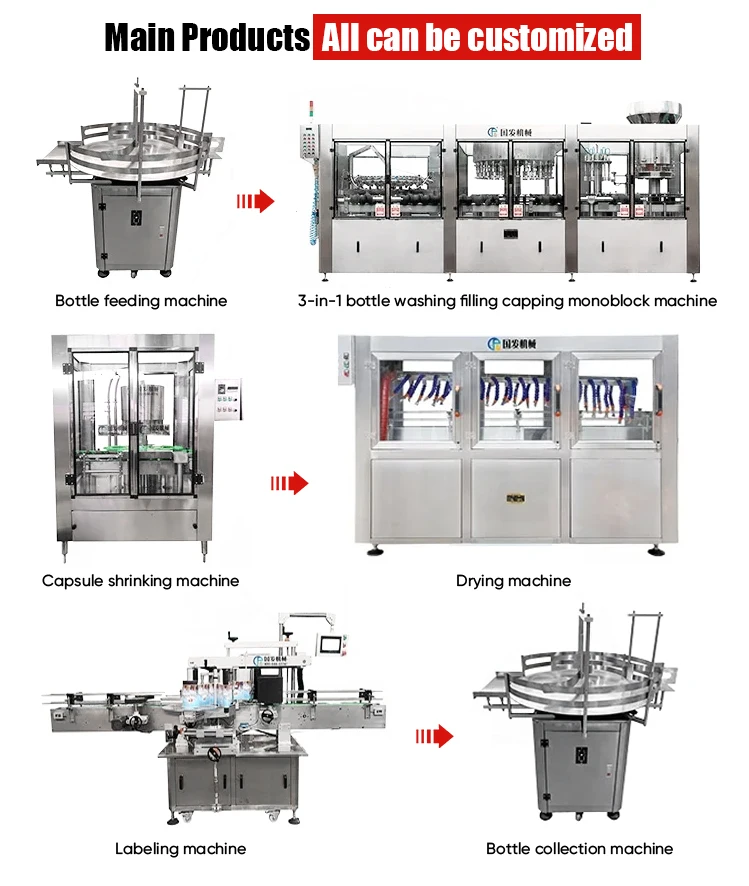

The whole machine is made by stainless steel and it is anti-rust and easy to clean. For this filling machine can also be

connected with other machines to form a production line.

Filling valve precision structure, less sealing parts, reliable and durable. And the structure is simple, disassembly,

convenient for cleaning.

The parts that contact with the filling liquid are made of high quality stainless steel to ensure that the filling liquid is not

contaminated and meets the food hygiene standards.