Manufacturing Industrial Material Handling Waste Paper Baling Press

SKU: RBL-2025021920262In Stock

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Manufacturing Industrial Material Handling Waste Paper Baling Press

Briefing

The product is designed for material handling in manufacturing industry factory workshops. It focuses on efficient and safe movement, storage, and control of materials within an industrial setting.

Key Features

- Efficiency: Streamlined processes to enhance productivity.

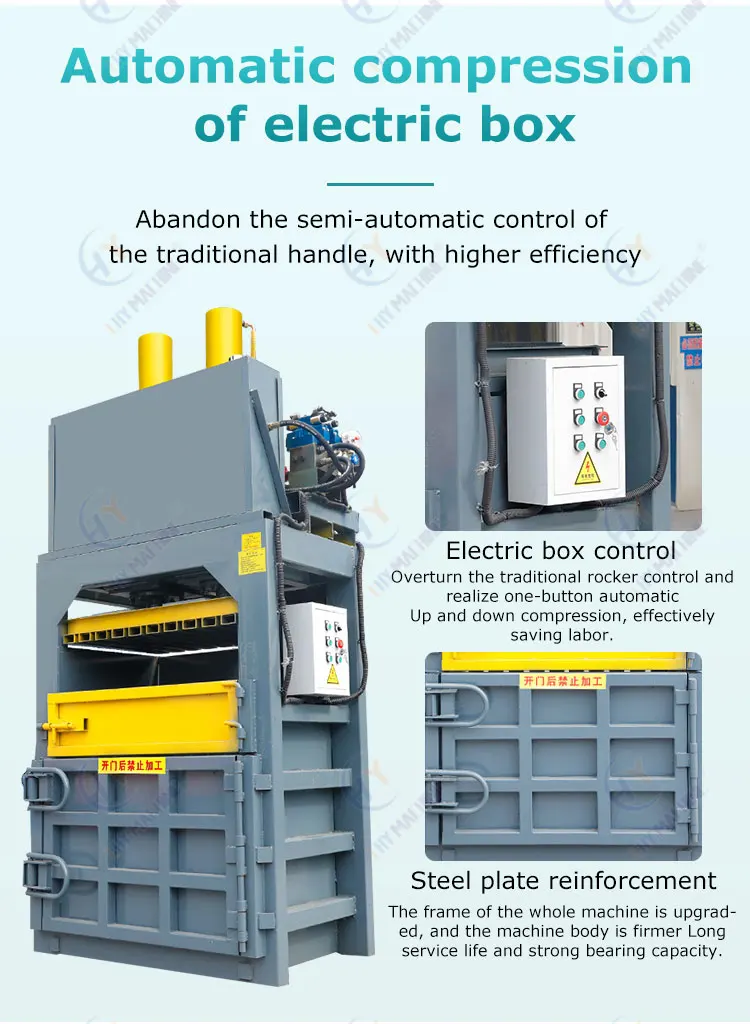

- Safety: Equipped with safety features to protect workers.

- Durability: Built with high-quality materials for long-lasting use.

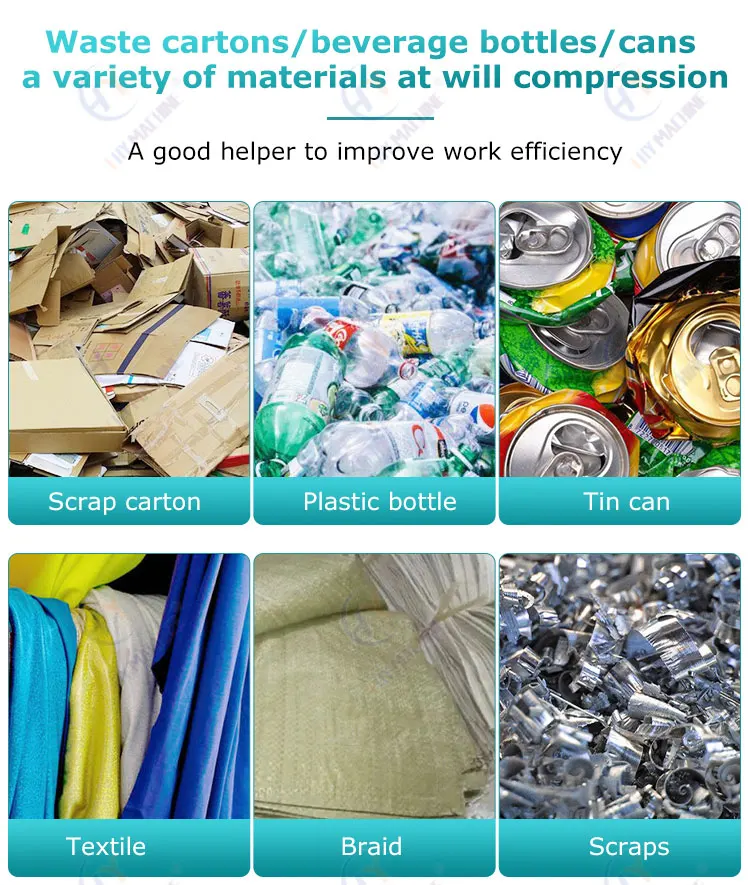

- Versatility: Suitable for various types of materials and applications.

- Automation: Incorporates automated systems for improved efficiency.

Specifications

- Material: High-quality industrial-grade materials.

- Capacity: Varies depending on the specific equipment and application.

- Power: Typically powered by electric or hydraulic systems.

- Dimensions: Varies by model, designed to fit within standard industrial spaces.

- Weight: Heavy-duty construction for stability and durability.

Applications

- Manufacturing Plants: Ideal for handling materials in production lines.

- Warehouses: Useful for organizing and moving inventory.

- Distribution Centers: Efficiently manages the flow of goods.

- Industrial Workshops: Enhances the overall workflow and productivity.

Summary

This material handling equipment is a robust and efficient solution for managing materials in industrial settings. With its focus on efficiency, safety, and durability, it is suitable for a wide range of applications, including manufacturing plants, warehouses, distribution centers, and industrial workshops. The incorporation of automated systems further enhances its productivity and reliability.

|

model

|

Motor(kw)

|

Package size

|

Overall

dimensions

|

oil pump

(mm)

|

Cylinder bore

|

Oil cylinder diameter

|

|

8T Single bar

|

4

|

600*400*600

|

1250*650*2150

|

306 Gear Pumps

|

80

|

90

|

|

10T Single bar

|

7.5

|

800*400*800

|

1450*650*2600

|

320 Gear Pumps

|

100

|

115

|

|

20T Single bar

|

7.5

|

800*400*800

|

1450*650*2700

|

325 Gear Pumps

|

125

|

140

|

|

30T Single bar

|

11

|

1000*600*800

|

1650*850*2750

|

532 Gear Pumps

|

140

|

160

|

|

30T Double bar

|

11

|

1000*600*800

|

1650*850*2700

|

532 Gear Pumps

|

100

|

115

|

|

40T Double bar

|

11

|

1000*600*800

|

1650*850*2750

|

550 Gear Pumps

|

125

|

140

|

|

60T Double bar

|

15

|

1200*800*1000

|

1600*2100*3100

|

563 Gear Pumps

|

140

|

160

|

|

80T Double bar

|

18.5

|

1200*800*1000

|

1700*2100*3300

|

563 Gear Pumps

|

160

|

180

|

|

100T Double bar

|

22

|

1200*800*1000

|

1700*2100*3900

|

563 Gear Pumps

|

160

|

180

|

|

120TFull steel plate

|

22

|

1100*700

|

1400*2000*4200

|

80YCY PZS

|

200

|

230

|

Product advantages.

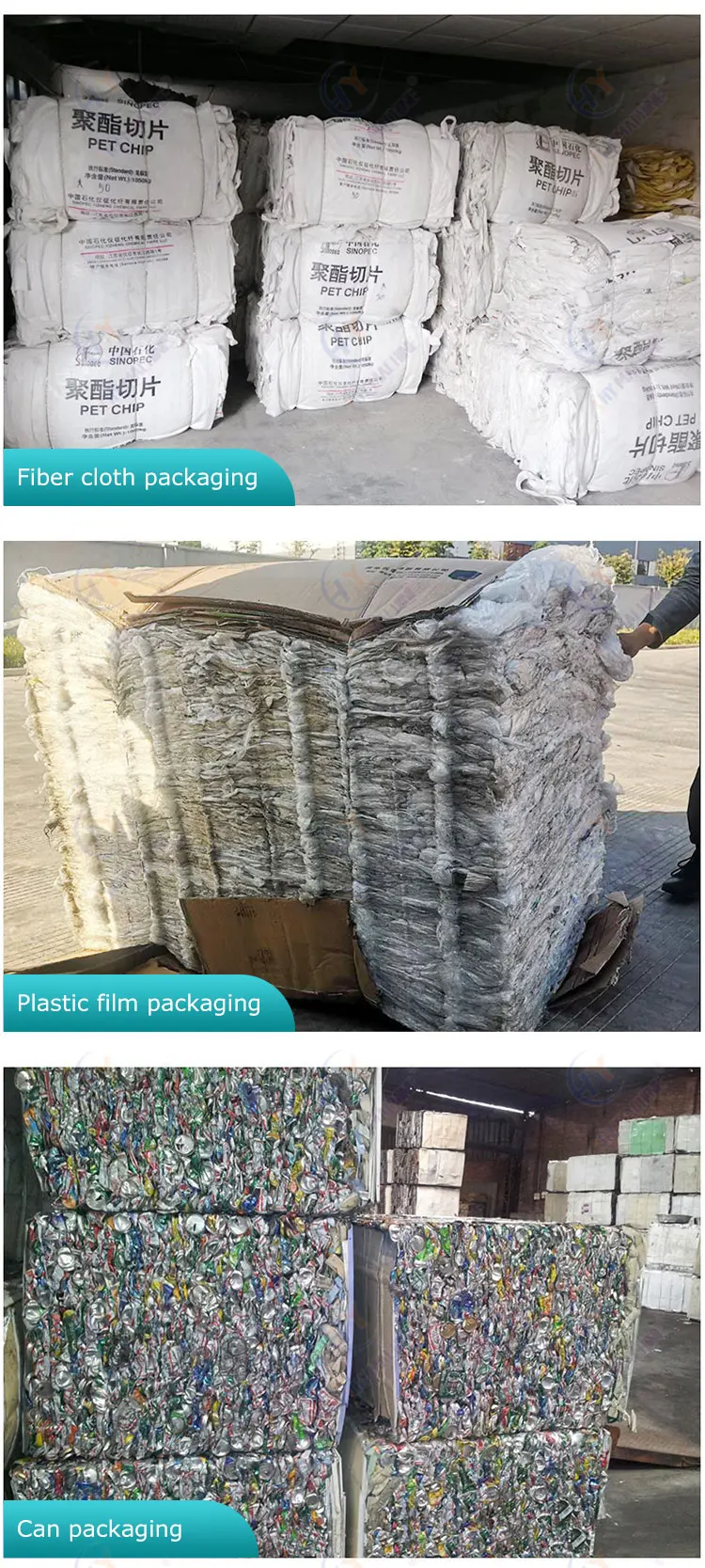

2. Completely maintain the physical characteristics of the material

3. The waste compaction ratio can reach 5:1

4. Two bundles for easy operation

5. Anti-rebound barb, keep compression effect

6. The platen automatically returns to position