Potato Chips Making Machine Frozen French Fries Production Line

SKU: RBL-2025030420268In Stock

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Potato Chips Making Machine Frozen French Fries Production Line

Briefing

The product is a Factory Price Industrial Fully Automatic Potato Chips Machine. This machine is designed for efficient and high-capacity use in various food processing settings, combining modern design with high-quality materials.

Key Specifications

- Type: Automatic

- Material: 304 Stainless Steel

- Operation: Fully Automatic

- Weight: Varies based on model

- Dimensions: Customizable

- Design Style: Modern and Functional

- Features: Easy Operation, High Efficiency

- Core Components: Motor

- Voltage: 220V/380V

- Power: 200W

- Capacity: 100 kg/h

- Warranty: 1 Year

- Video Outgoing-Inspection: Provided

- Machinery Test Report: Provided

Applications

- Potato Chips Processing: Ideal for use in potato chips production.

- Food Processing: Suitable for various food processing applications.

- Commercial Use: Designed for commercial use in food factories, farms, restaurants, and food shops.

Summary

This factory price industrial fully automatic potato chips machine offers a powerful and efficient solution for enhancing the productivity and functionality of various food processing spaces. It is designed for fully automated operation, making it suitable for different environments. The machine is customizable in terms of size and specifications, providing flexibility for different needs. Its durable construction and modern design ensure reliable performance and a touch of sophistication.

Product Description

Automatic Frozen French Fries production line is used to produce frozen French fries / potato chips from fresh potatoes, with capacity from 100-2000 kg/h for selection.

|

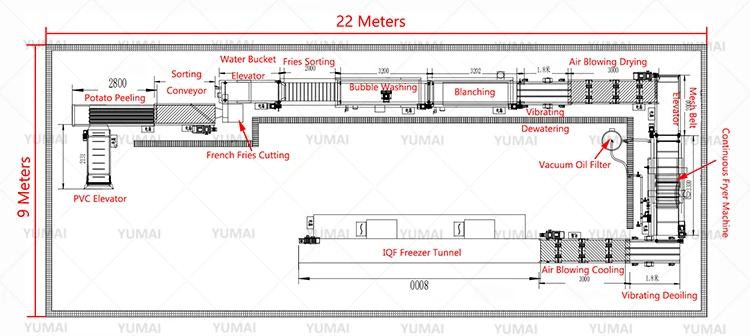

Fully Automatic Frozen French Fries Production Process: |

|||||

|

No. |

Machine Name |

Dimension | Power | Quantity | Material |

|

1 |

PU Belt Elevating Conveyor |

2400*700*1600mm |

0.75kw |

1set |

SUS304 |

| 2 | Potato Washing & Peeling Machine | 3400*1000*1400mm | 4.37kw | 1set | SUS304 |

| 3 | Sorting Conveyor | 3000*700*900mm | 0.75kw | 1set | SUS304 |

| 4 |

French Fries Cutting Machine |

950*800*950mm | 1.5kw | 1set | SUS304 |

| 5 | Water Tank Elevator | 2200*800*1600mm | 0.75kw | 1set | SUS304 |

| 6 | Fries Sorting Machine | 2400*1000*1300mm | 2kw | 1set | SUS304 |

| 7 | Bubble Washing Machine | 4000*1200*1400mm | 6kw | 1set | SUS304 |

| 8 | Blanching Machine | 5000*1200*1400mm | 140kw | 1set | SUS304 |

| 9 | Vibrating Dewatering Machine | 1800*1000*1300mm | 0.36kw | 1set | SUS304 |

| 10 | Air Drying Machine | 4000*1000*1600mm | 7.5kw | 1set | SUS304 |

| 11 | Mesh Belt Elevating Conveyor | 2000*800*1300mm | 0.75kw | 1set | SUS304 |

| 12 | Continuous Frying Machine | 6000*1200*1400mm | 200kw | 1set | SUS304 |

| 13 | Vibrating Deoiling Machine | 1800*1000*1300mm | 0.36kw | 1set | SUS304 |

| 14 | Cooling Machine | 4000*1000*1600mm | 7.5kw | 1set | SUS304 |

| 15 | Mesh Belt Elevating Conveyor | 2000*800*1300mm | 0.75kw | 1set | SUS304 |

| 16 | IQF Freezer Tunnel | 11500*2200*2200mm | 90kw | 1set | SUS304 |

| 17 | Elevating Conveyor | 3000*500*1400mm | 1.1kw | 1set | SUS304 |

| 18 | Automatic Packing Machine | 5000*2000*3400mm | 6.7kw | 1set | |

1.Clean It is mainly divided into two parts: peeling and cleaning. The main equipment is automatic peeling and cleaning machine and air bubble cleaning machine. After peeling the potato, this step is to clean it again to meet the clean standard. 2.Cut/Slicing

Cleaning the picked potatoes automatically entered the cutting machine and cut it. The ma-chine absorbs the advantages of similar products, it has the advantages of reasonable structure, high efficiency, energy -saving consumption, simple operation, etc. The material is uni-form, beautiful, and less consumed.

3.Select Siege the fries after cutting and eliminate unqualified products

4. Rinse Wash the surface starch on the fries

5. Blanching After the rinsing, the fries entered the drifting stage and carried out color protection and sterilization

7. Air -drying Dry the water remaining on the surface of the French fries on the surface of the hot flies, which can maintain the original shape of the fries to a greater extent.

8. Frying Use oil and water to separate the fried fryer, with controllable temperature, maintain the original flavor

9. Air -drying Dry the fried fried fries to avoid the taste and taste of residual oil residue affecting the fries.

10. Frozen

11.Package Using automatic weighing packaging machines, fast speed and high efficiency.