Tissue Toilet Paper Making Machine Without Core Toilet Paper Rewinding Machine

SKU: RBL-2025021720257In Stock

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Tissue Toilet Paper Making Machine Without Core Toilet Paper Rewinding Machine

Briefing

This tissue toilet paper making machine is designed for producing high-quality toilet paper rolls. It features advanced technology and automation to ensure efficient and consistent production.

Specifications

- Standard Width of Jumbo Roll: 1390mm or 1850mm

- Daily Capacity: >12 tons/day (8 layers, 13.5 g/㎡, 24 hours)

- Tissue Paper Layers: 2-4 layers

- Tissue Paper Grammage: 2 layers: 13.5-18 g/㎡ per layer; 3-4 layers: 11-15 g/㎡ per layer

- Tissue Folding Capacity: 13 strips/min

- Production Capacity: 12 strips/min or 110 m/min

- Control System: PLC control with large screen HMI operation

- Drive System: Servo & variable frequency drive

- Technology: Mechatronics with automatic detection and adjustment

Key Features

- High Automation: The machine can complete the entire process of tissue paper embossing, folding, counting, cutting, and packaging with a high degree of automation.

- Efficient Production: Capable of producing over 12 tons of tissue paper per day.

- Advanced Control System: Equipped with PLC control and large screen HMI operation for easy monitoring and control.

- High-Quality Output: Produces high-end facial tissues with consistent quality.

- Versatile: Suitable for producing various types of tissue paper products.

Applications

- Household Paper Processing: Ideal for producing high-end facial tissues and other tissue paper products.

- Commercial Use: Suitable for large-scale production in tissue paper manufacturing plants.

- Industrial Use: Can be used in industries requiring high-quality tissue paper products.

Summary

The tissue toilet paper making machine is a highly efficient and automated solution for producing high-quality tissue paper products. With its advanced technology and high production capacity, it is an excellent choice for household paper processing enterprises and large-scale manufacturing plants.

|

Machine Model

|

1575/1880//2400/3000/S3000

|

|

Paper Width(mm)

|

Max 1750mm/2200mm/2400mm/3000mm/3050mm

|

|

Paper Diameter(mm)

|

φ1150mm(Please Specify)

|

|

Paper Core Inner Diameter

|

φ76mm(Please Specify)

|

|

Product Diameter

|

φ50mm-180mm

|

|

Paper Backing

|

1-4layer,general chain feed or continuously variable transmission feed paper

|

|

Punch

|

2-4 Knife, Spiral Cutter Line

|

|

Hole Pitch

|

Positioning of Belt and Chain Wheel

|

|

Control System

|

PLC Control, Variable Frequency Speed Control, Touch Screen Operation

|

|

Product Range

|

Core Paper, Non Core Roll Paper

|

|

Drop Tube

|

Manual, Automatic(Optional)

|

|

Non core roll paper

|

automatic core pulling

|

|

Production Speed

|

80-200m/min

|

Four-roller automatic feeding →synchronous conveying →embossing →punching →automatic winding →cutting→ packing →sealing.

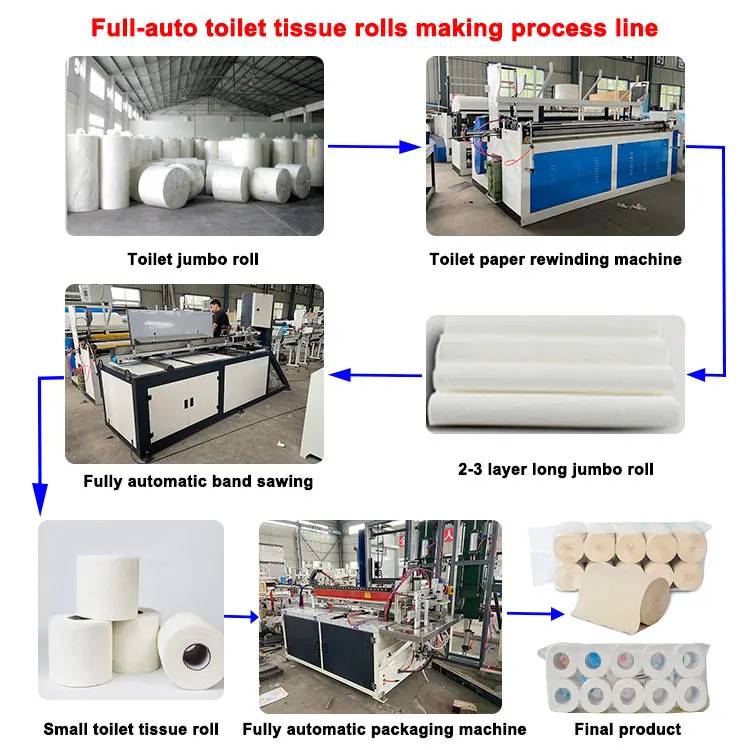

1. Rewinding—The main purpose of the toilet paper rewinding machine is to process the large shaft paper into a long strip of toilet paper roll.

2. Cut the paper—The long piece of toilet paper cut by the paper cutter is cut into semi-finished products of the length

required by the customer.

3. Packaging—Packaging can be packaged in a packaging machine or manually wrapped, and the semi-finished products of the toilet paper are packaged and sealed by a sealing machine.