Automatic High Speed Wood CNC Cut Off Saw Machine for Wood Pallet

SKU: RBL-2025022220264In Stock

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Automatic High Speed Wood CNC Cut Off Saw Machine for Wood Pallet

Briefing

The product is an Automatic High-Speed Wood CNC Cutting Machine. This machine is designed for efficient and precise cutting of wood using CNC technology.

Key Specifications

- Type: CNC Cutting Machine

- Material: Steel

- Operation: Automatic

- Power: 15 kW

- Voltage: 380V/50Hz

- Cutting Length: 400mm to infinity

- Cutting Width: 20-200mm

- Cutting Thickness: 12-80mm

- Rotary Speed: 4500 RPM

- Weight: Approximately 1000 kg

- Dimensions: Customizable

- Control: Electric

Applications

- Woodworking: Ideal for cutting wood in various woodworking projects.

- Furniture Manufacturing: Suitable for manufacturing furniture and decorative items.

- Customizable: Can be customized for different sizes, colors, and logos.

Summary

This automatic high-speed wood CNC cutting machine offers a powerful and efficient solution for cutting wood. It is designed for automatic operation with a high-precision control system, making it suitable for use in various industries such as woodworking and furniture manufacturing. The machine is customizable in terms of size, color, and logo, providing flexibility for different projects. Its durable construction and advanced control features ensure reliable performance.

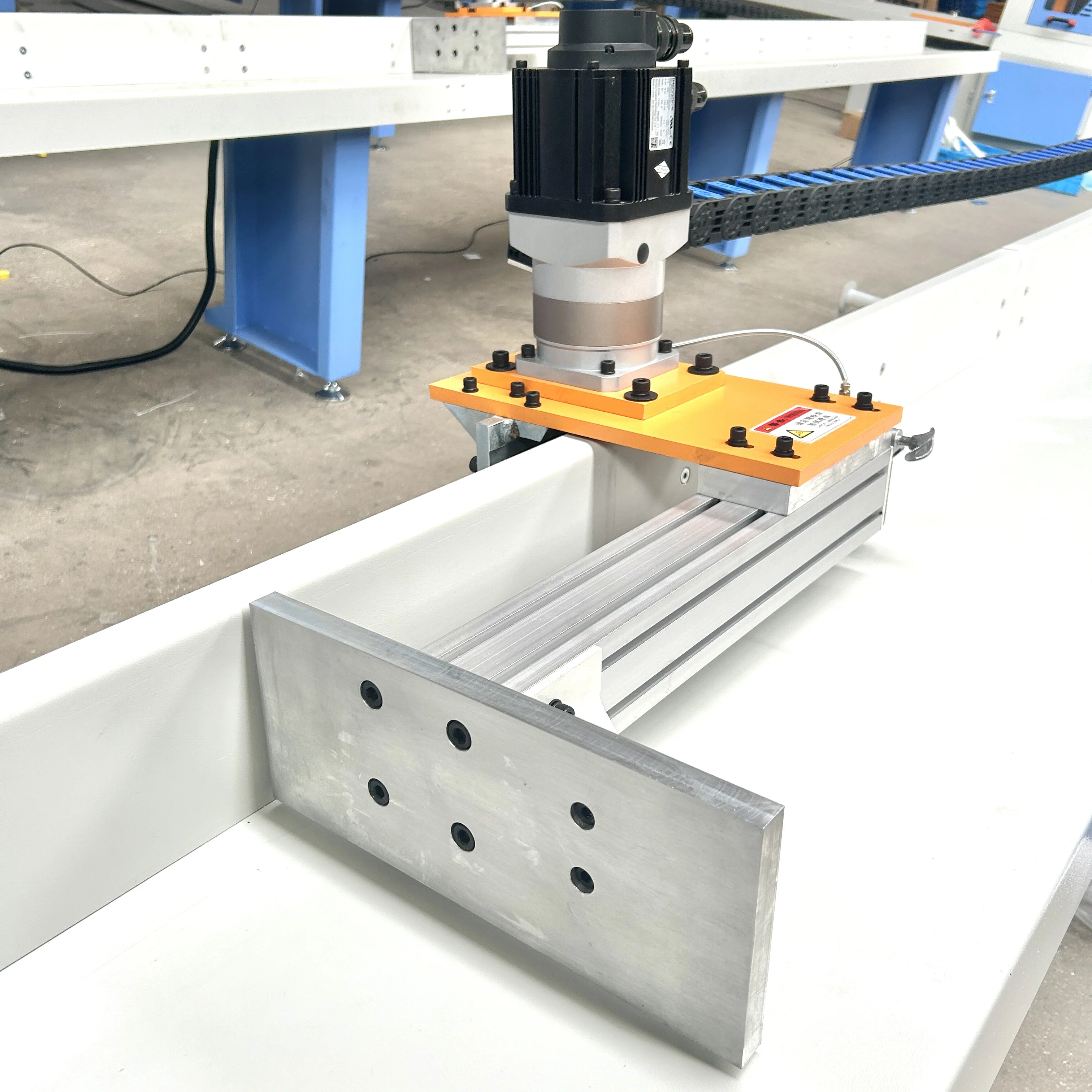

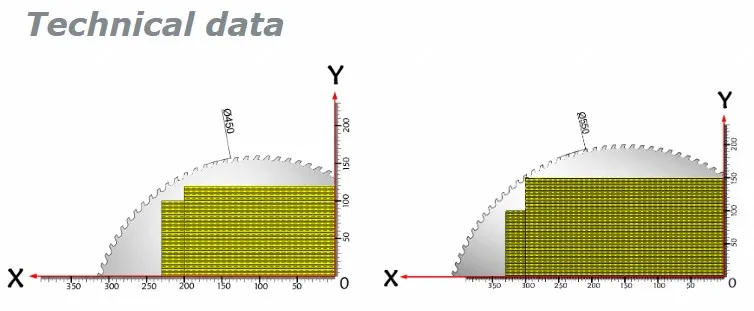

Automatic Push Feed Saw BCC-450

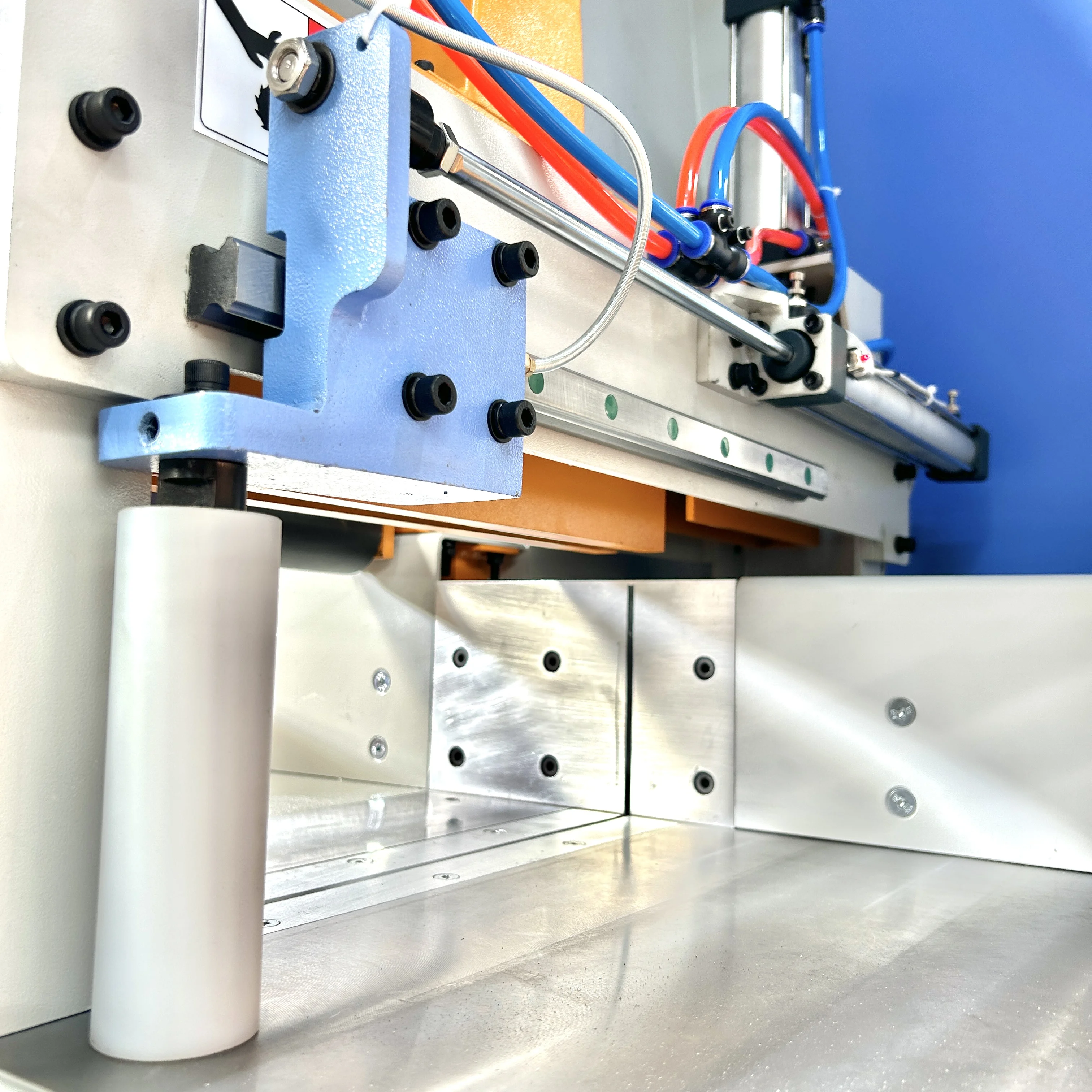

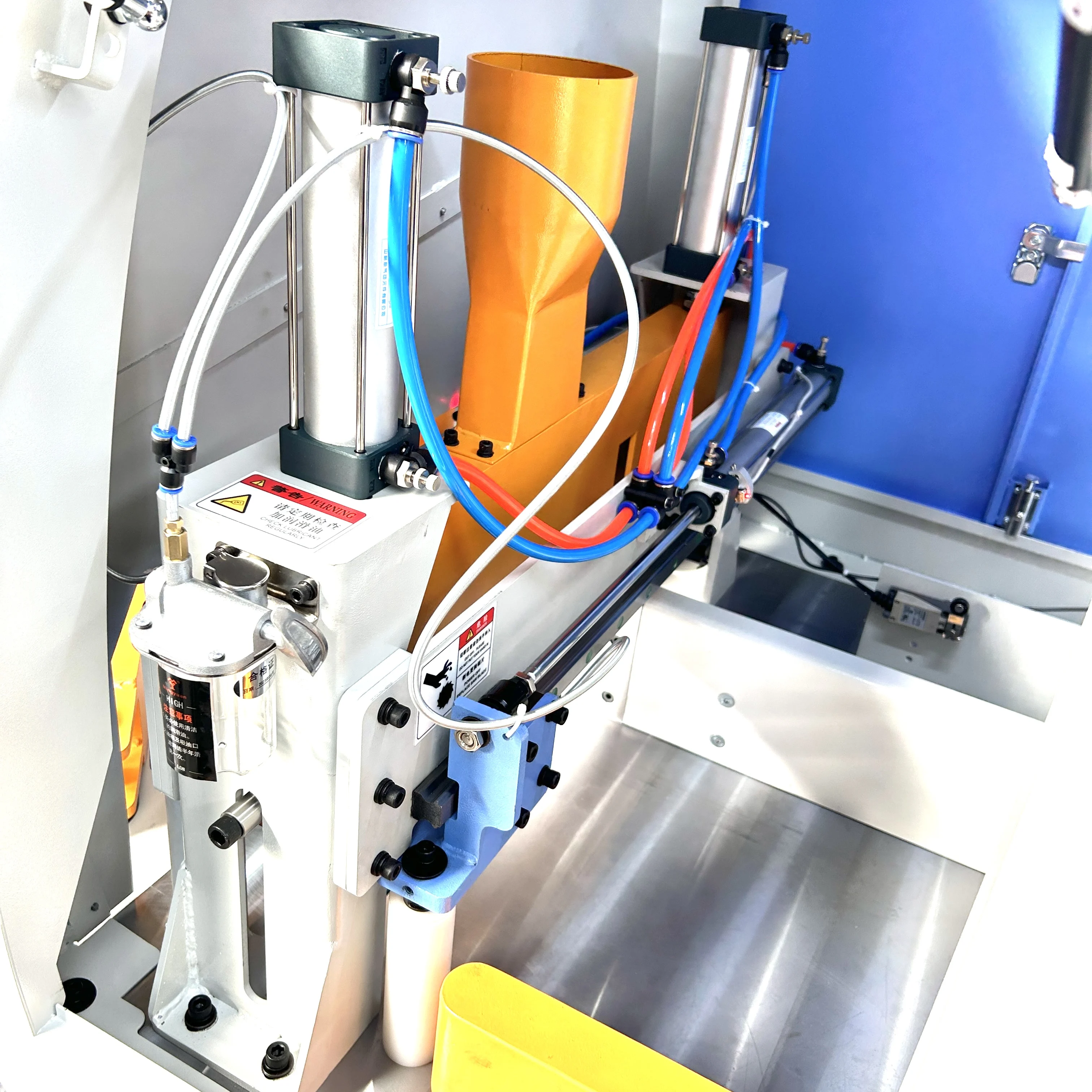

Internal side clamp

Top pressing structure

Safety, efficiency, and accuracy

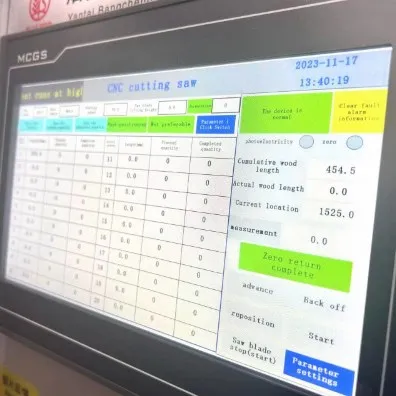

It contains cutting program, input different length and quantity you want to cut from the touch screen, then machine will cut automatically.

It can be placed with multiple pieces of wood and timber for your large quantity production needs, and minimizes labor and improves efficiency.

|

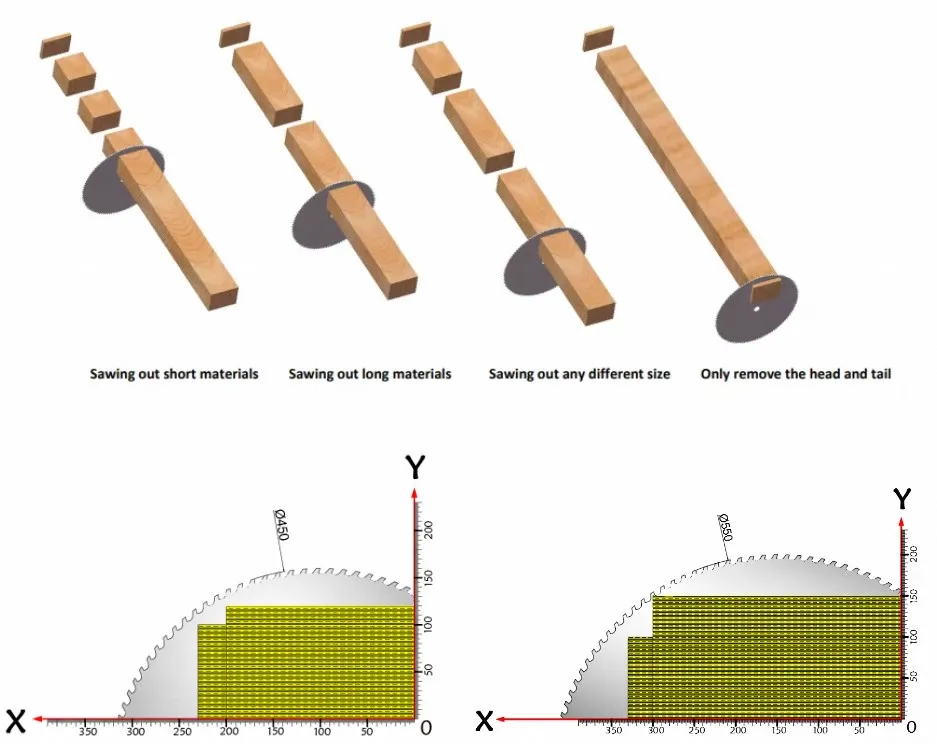

Model

|

BCC-450

|

BCC-550

|

|

Feed pushing servo motor

|

1.3kw

|

1.3kw

|

|

Saw blade type

|

450*3.6*3.0*100T

|

550*4.8*4.6*120T

|

|

Sawing size

|

200*120(mm)

|

300*150(mm)

|

|

Sawing accuracy

|

±0.3mm

|

±0.3mm

|

|

Pushing conveyor mode

|

Rack and pinion

|

Rack and pinion

|

|

Saw blade motor

|

5.5kw

|

7.5kw

|

|

Main engine size(mm)

|

1000*900*1650

|

1100*1000*1700

|

|

Feed platform length

|

3m/5m/7m(Optional)

|

|

|

Discharge platform length

|

1.5m(Optional)

|

|

|

Saw blade speed

|

3060r/min

|

|

|

Feeding speed

|

0-60m/min

|

|

|

Reverse speed

|

0-70m/min

|

|

|

Voltage

|

380v 50hz 3phase

|

|

BCZ-6000

BCW-6000

upstroke crosscut saw for cutting both straight and angled timber components.