Facial Tissue Converter Facial Tissue Spray Perfume Machine

SKU: RBL-2025022020254In Stock

Important Notice. Delivery is estimated to take up to 60 days, please contact our sale support. View Shipping Policy

Warranty. This product has passed all the required quality check

Description

Facial Tissue Converter Facial Tissue Spray Perfume Machine

Briefing

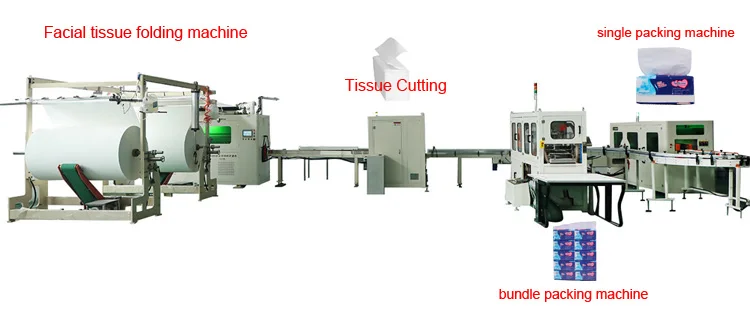

The product is a Facial Tissue Converting Making Machine. This machine is designed for the efficient production of facial tissues, transforming raw materials into finished products through a series of automated processes.

Key Features

- Material: Made from high-quality materials for durability and longevity.

- Design: Ergonomic and user-friendly design for ease of operation.

- Efficiency: High production efficiency ensures consistent and accurate tissue making.

- Automation: Fully automated processes, including folding, cutting, and packaging.

- Safety: Equipped with safety features to protect operators.

Specifications

- Material: High-quality industrial-grade materials.

- Capacity: Varies depending on the model, typically around 60-100 packs per minute.

- Power: Typically powered by electric systems.

- Dimensions: Varies by model, designed to fit within standard industrial spaces.

- Weight: Heavy-duty construction for stability and durability.

Applications

- Tissue Manufacturing Plants: Ideal for producing large quantities of facial tissues.

- Paper Product Factories: Suitable for integrating into existing paper product manufacturing lines.

- Commercial Use: Useful for businesses looking to produce their own branded facial tissues.

- Industrial Facilities: Efficiently handles the production of facial tissues for various industrial applications.

Summary

The Facial Tissue Converting Making Machine is a robust and efficient solution for producing facial tissues. With its high-quality materials, ergonomic design, and high production efficiency, it ensures consistent and accurate tissue making. This machine is versatile and suitable for a wide range of applications, including tissue manufacturing plants, paper product factories, commercial use, and industrial facilities.

2, Four knife type folding roller system, Big roller diameter reduce stress deformation, Stable cutting

off with good effect;

3, Folding roller with V type suction slot, With long vacuum ventilation time, Vacuum pump is more energy efficient;

4, Side conveying type structure ,The equipment occupies a smaller area, Save factory floor space;

5,High integration, Easy installation and debugging, Quickly Installation and put into production ;

|

Configuration:

|

|

|

Unwinding stander

|

2 sets

|

|

Jumbo roll max width

|

1520mm; 1880mm; 2080mm

|

|

Jumbo roll max diameter

|

<=1550mm

|

|

Jumbo roll inner core diameter

|

76.3mm

|

|

Unwinding belt

|

Sheet base paper feed belt

|

|

Unwinding speed adjustment

|

Individual speed adjustment for each stander via touch screen

|

|

Jumbo roll Left /right adjustment

|

hand wheel

|

|

Loading manner

|

Pneumatic cylinder loading

|

|

Driving type

|

Independent servo motor 1.5kw

|

|

Main folding machine

|

1 set

|

|

Main frame

|

Wallboard type

|

|

Folding specification L(mm)

|

Paper cutting length=L (+0, -3),L : 175/180/190/200mm as request

|

|

Folding width B(mm)

|

B=L/2 (+2, 0)

|

|

Folding height H(mm)

|

H=40-400 (Folding width, not packing height

|

|

Folding type

|

Vacuum adsorption V type interfold

|

|

Cutting paper face knife roller

|

Adopt spiral knife roller structure, knife is of high stable and durable

|

|

Folding roller

|

4 paper bottom knives evenly distributed on folding roller, with the suction

V-slot, the suction and operation are more stable |

|

Embossing base roller

|

Adopt bearing steel with heat treatment, hardness above HRC60, long service

life |

|

Edge embossing set

|

Steel to steel ,or steel to rubber; pressing embossing roller by air bag

|

|

Vacuum pump

|

Standard 30KW Roots vacuum pump , Build in type 22KW vacuum pump

can be customized |

|

Folding motor power

|

Conventional configuration 7.5KW

|

|

Operation interface

|

10.4-inch man-machine interface (touch screen

|

|

Separating part

|

|

|

Automatic tissue strip separating

|

With full servo system control, automatic stacking and separating

|

|

Running type

|

Each pawl independent servo operation, the whole machine run linkage

|

|

Automatic counting

|

Adopt High precision encoder

|

|

Folding pulls number setting

|

100% accurate adjustment paper counts (based on an even number of counts)

|

|

Pulls number setting range

|

2ply 100-400 pulls; 5 ply 40-240 pulls

|

|

Stacking speed

|

Maxi. 13 strips/min

|

|

Power

|

Approx. 5.5KW

|

|

Automatic log saw cutting machine:

|

|

|

Independent electric control box

|

|

|

A set of sharpener (mounted on the swing arm)

|

|

|

Two servo motors (installed in the machine)

|

|

|

A large round knife (installed in the machine)

|

|

|

A PLC programmer (installed in the electric control box)

|

|

|

A frequency converter (installed in the electric control box

|

|

|

One touch screen (installed in the electric control box)

|

|

|

A set of paper head and paper tail removal system (installed in the machine)

|

|

Facial tissue single packing machine

|

|

|

Package specification

|

≤ 200 * 95 * 100 mm

|

|

Packaging speed:

|

20-200 bags / min

|

|

Air pressure

|

0.5-0.8mpa

|

|

Power supply voltage

|

380V, 50Hz

|

|

Total power

|

19kw

|

|

Weight

|

3000kg

|

|

Packaging material

|

CPP

|

|

Overall dimension

|

6010 * 4220 * 1537 mm

|

|

facial tissue bundle packaging machine

|

|

|

Designed speed

|

45 bundles/min

|

|

Production speed

|

13-40 bundles/min

|

|

Packaging type

|

1-3 rows, 3-10bags/row

|

|

Packing shape

|

Lateral packing

|

|

Machine power

|

8.0KW

|

|

Air pressure

|

0.5Mpa

|

|

Machine weight

|

1500KG

|